In the world of machinery and industrial equipment, precision is paramount. Misalignment can lead to significant issues, including increased wear and tear on components, higher energy consumption, and unexpected downtime. One of the most effective ways to ensure proper alignment of pulleys is through the use of a laser pulley alignment tool. This article explores the key benefits of employing such tools for maximum accuracy.

Understanding Laser Pulley Alignment

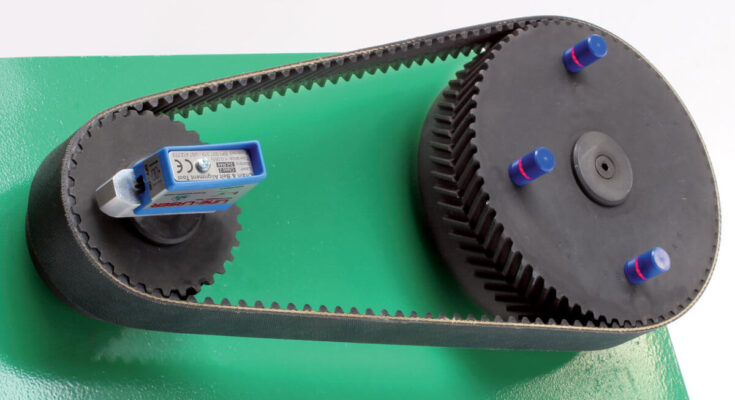

Before delving into the benefits, it’s essential to understand what laser pulley alignment involves. This process uses a laser beam to measure the alignment of pulleys within a system. Unlike traditional methods, which may rely on visual inspections or less precise measuring tools, laser alignment offers a high degree of accuracy. This technology significantly reduces the margin for error, making it an invaluable asset in maintenance routines.

1. Enhanced Precision

One of the primary advantages of a laser pulley alignment tool is the level of precision it provides. Traditional alignment methods often suffer from human error and mechanical inaccuracies. With laser technology, measurements are taken in real-time, allowing for immediate adjustments. This ensures that the pulleys are aligned within the manufacturer’s specifications, minimizing the risk of misalignment-related issues.

2. Reduced Downtime

Downtime can be costly for any business. Misaligned pulleys can lead to equipment failure, requiring repairs that take time and resources. By utilizing a laser alignment tool, maintenance teams can quickly and accurately align pulleys, significantly reducing the amount of time machines are out of operation. This efficiency not only saves money but also helps maintain productivity levels.

3. Improved Equipment Lifespan

Proper alignment is crucial for the longevity of machinery. When pulleys are misaligned, they exert additional stress on bearings and other components, leading to premature wear. By employing a laser pulley alignment tool, operators can ensure that the pulleys are aligned correctly, reducing the strain on equipment. This can extend the lifespan of both the pulleys and the associated machinery, resulting in lower replacement costs over time.

4. Increased Energy Efficiency

Misalignment can lead to increased energy consumption as motors work harder to compensate for the inefficiencies created by poorly aligned pulleys. This extra energy expenditure not only raises operating costs but also contributes to unnecessary wear on components. With the precision offered by a laser alignment tool, businesses can achieve optimal alignment, reducing energy consumption and lowering costs in the long run.

5. Enhanced Safety

Safety is always a priority in any industrial setting. Misaligned machinery can create hazardous conditions, including vibrations that lead to unexpected equipment failures. By ensuring that pulleys are aligned correctly with a laser tool, businesses can mitigate the risks associated with misalignment. This not only protects employees but also helps prevent costly accidents and repairs.

6. User-Friendly Operation

Modern laser pulley alignment tools are designed with user-friendliness in mind. Many of these tools come equipped with intuitive interfaces and clear instructions, making them accessible even to those who may not have extensive technical training. This ease of use allows maintenance teams to quickly adopt and integrate laser alignment into their regular routines, maximizing efficiency.

7. Data Recording and Analysis

Another significant benefit of using a laser alignment tool is the ability to record and analyze alignment data. Many tools come equipped with software that tracks measurements over time, allowing for trend analysis and proactive maintenance planning. This data-driven approach can help businesses identify recurring issues and implement solutions before they escalate into more significant problems.

8. Cost-Effectiveness

While the initial investment in a laser pulley alignment tool may be higher than traditional alignment methods, the long-term savings can be substantial. Reduced downtime, improved equipment lifespan, and lower energy costs all contribute to a favorable return on investment. Businesses that prioritize precision and efficiency often find that the benefits outweigh the costs.

9. Environmental Impact

In today’s world, sustainability is an essential consideration for any business. By improving energy efficiency and reducing waste, companies can lessen their environmental footprint. Laser alignment helps ensure that machines operate at peak efficiency, resulting in less energy consumption and fewer emissions. This not only benefits the planet but can also enhance a company’s reputation among environmentally conscious consumers.

Conclusion

Incorporating a laser pulley alignment tool into maintenance practices offers numerous advantages that can transform the way businesses approach machinery management. From enhanced precision and reduced downtime to increased energy efficiency and improved safety, the benefits are clear. As industries continue to prioritize efficiency and sustainability, laser alignment tools will play a crucial role in achieving these goals.

Investing in a laser pulley alignment tool is not just about keeping equipment running smoothly; it’s about embracing a proactive maintenance strategy that safeguards your operations. By leveraging the power of technology, businesses can ensure that their machinery operates at optimal levels, ultimately leading to improved productivity and profitability.